The Best Guide To Insulated Spandrel Panel

Table of ContentsSome Known Details About Curtain Wall Spandrel Panel Detail 6 Easy Facts About Kawneer Spandrel Panel Metal Spandrel ExplainedThe Main Principles Of Roof Spandrel Panels

Weathering is accomplished by zone drained pressure equalisation. The glazing supplies a favorable weather seal for high performance. The system additionally includes the unique, high efficiency thermal break. The AA265 unitised system gives the specifier a large selection of styles to develop specific and amazing building exteriors. The AA265 can suit spandrel infill materials consisting of glass, rock as well as metal panels.The system is suitable for rapid track installation where safe approaches of work are required. The AA265 has actually been exclusively developed and created by Kawneer, with setup contracts taken on in collaboration with its network of authorised dealerships (kawneer spandrel panel metal spandrel). The AA265 has actually been evaluated as well as certified in conformity with the CWCT Series B 2006 Requirement for Systemised Structure Envelopes.

Drape wall and also store glazing systems are normally a slim, non-structural outer faade component of a building that can span several floorings or be integrated right into a punched opening. Polishing systems operate greatly as air as well as water vapor barriers, withstanding air or water seepage and fit building and also system motion caused by wind, thermal, and also seismic pressures.

Because of this, lightweight products can be used in their growth. Business glazing systems are typically created of aluminum-framed walls with glass, steel panels, louvers, operable home windows or vents, or rock veneer infills. Structure envelope experts will certainly usually encourage developers on curtain wall surface and also storefront needs for developing movement, thermal development as well as contraction, water diversion, and thermal efficiency.

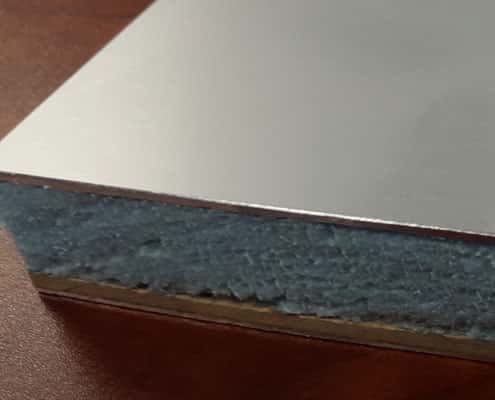

Opaque glazing, metal panels, MCM (steel composite products) panels, or shielded laminated panels are commonly utilized as spandrel infill. When insulation is made use of inboard of the spandrel infill, an air space is consistently presented to stop thermal damages to the spandrel infill. Unfortunately, the air area can give a possibility for condensation to develop on the indoor face of the spandrel infill.

The Greatest Guide To Insulated Spandrel Panel

Condensation development on spandrel infill is most likely to occur throughout extreme winter months problems when not enough warm is provided from the inside to avoid indoor infill surface area temperature levels from continuing to be over the humidity. When indoor surface temperatures dip below the dew point, water particles begin to base on the interior surface area of the spandrel infill (gable spandrel panel).

Need to badly created spandrel conditions be left ignored, condensation can lead to moisture or visual damages to the spandrel panel and/or interior surfaces. When condensation kinds at the spandrel infill of a glazing system, several kinds of damage can happen, as well as the results of condensation can be significant. Along with wetness damage and also microbial development, condensation growth on spandrel infill can likewise have an unfavorable result.

This wetness can be taken in by the bordering parts, causing damages to the setting up as well as adjacent surface areas. As condensation creates in these unventilated areas, microbial growth might develop and infect nearby areas, creating more damage. Condensation buildup in these locations can harm glazing spandrel finishings. On top glass glazing manufacturers of that, mixes of these sorts of damage can happen, creating modern damage that will certainly call for expert remediation.

One method to postpone the development of condensation on the glazing system spandrel infill is to use the structure A/C system. By increasing airflow near these places, even more heat will certainly be moved to the setting up and boost interior surface area temperature levels. One more means to utilize the HVAC system is by decreasing the interior family member moisture established points relative to outside temperature.

One more technique of discouraging condensation is by sealing the horizontal-to-vertical mullion joints at the spandrel cavity to prevent unchecked air movement into the cavity. gable spandrel panel. Usually, an uncontrolled interior is moisture laden and when it comes into call with the spandrel infill, which is below the dew point, it enhances the quantity of condensation formation.

Roof Spandrel Panels Fundamentals Explained

Along with including rehabilitation methodology, means to decrease condensation capacity throughout design consist of: Commonly drape wall systems have greater resistance to condensation than store front systems. Using curtain wall surface is one method to minimize, or postpone the start of condensation development. At Pie, we supply 2-D thermal modeling (THERM) to help our customers with the design of spandrel locations.

By recognizing surface temperature levels, Pie is able to identify under which problems condensation will occur, in addition to identify transition factors at which condensation will not develop, making it much easier to predict as well as remediate. Additionally, numerous configurations can be modeled to maximize indoor surface temperature levels. Setting up back pans into the spandrel infill glazing pocket, which are aired vent to the outside with insulation outboard of the pan, promotes increased interior surface temperatures with the included advantage of double pane tempered glass panels decreasing warm transfer via the spandrel infill.

It is feasible to take full blog advantage of interior surface area temperatures by removing the use of insulation at the spandrel infill place. Keep in mind if you make without insulation at spandrel infill areas, there will be a greater power loss through the assembly and also therefore bigger HVAC warmth tons. At Pie, we can aid you each action of the way, whether you lately uncovered condensation as well as are looking for removal and also management services, or whether you are making a structure and aim to reduce the possibility for condensation at spandrel infill places.

Glaz-Tech Industries introduces GlazeGuard 250WR and GlazeGuard1000 WR infill panels to further give extra building remedies for store and window systems. Its sturdy and eye-catching style contributes with store front applications as well as insulated systems. Glaz-Tech's infill panels use several building advantages: GlazeGuard WR panels are highly effective versus dampness intrusion and likewise excellent for setup because of its lightweight style.

With a number of different make-ups and also finish options, GlazeGuard can offer a cost-effective choice to other polishing solutions while still supplying aesthetic interest and worth. Little or no upkeep is called for and most grease, dust, oil as well as other foreign product can be quickly cleaned from the surface. Glaz-Tech stocks Metallic Silver, Shasta White as well as Classic Bronze.